GO-SHIP IO5: CTD Casting

CTD Watch-standers Log: CTD Casting

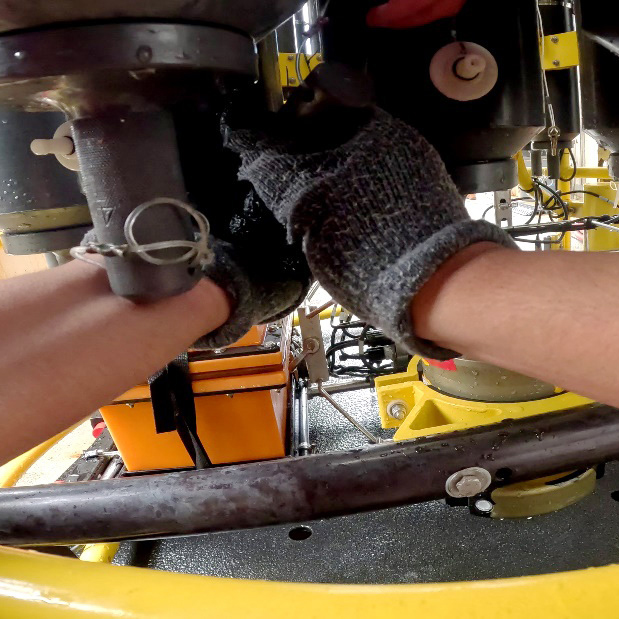

In one cycle of CTD casting, we start with a process called “cocking” where we need to manually pull out the top and bottom caps of the Niskin bottles (Rosette bottles) and hook them to the hinges on the water samplers (aka. the carousel). The top and bottom caps are connected with springs so that once the rosette is in the water, the operator can control the water samplers and trigger the water samplers to release the hinges corresponding to the desire bottle. Here, the seawater at the target depth is trapped inside the bottle.

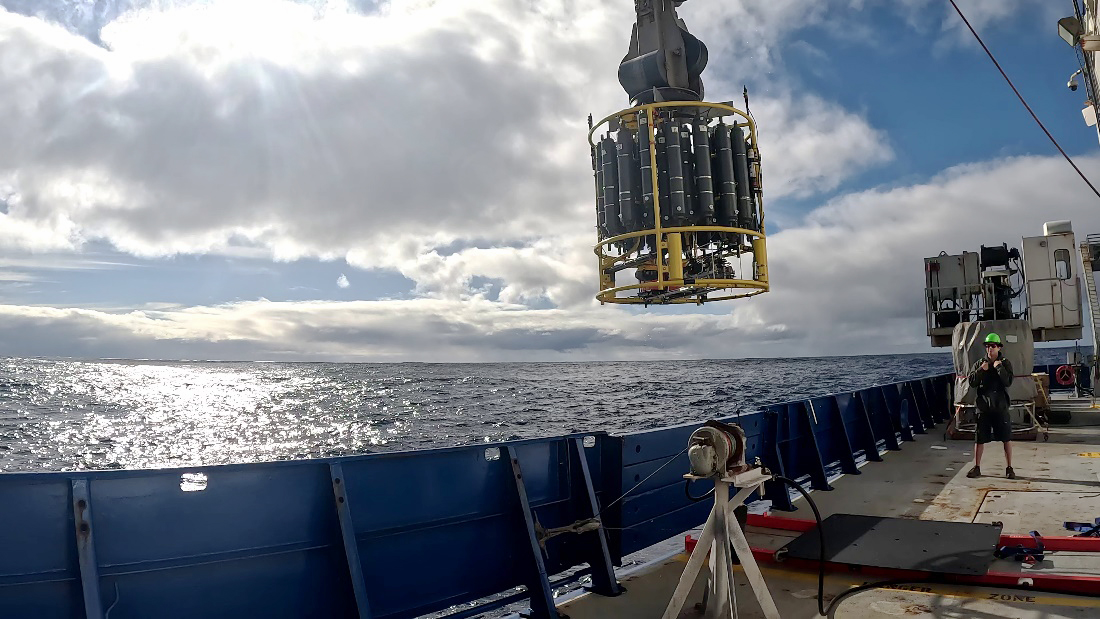

Once all the bottles are cocked, the CTD rosette is ready to deploy. At the sampling station, the CTD rosette is transported from the hangar to the deck. Then, the rosette will be lifted up and deployed into the ocean by a winch.

The rosette will be casted down to the about 10m above the seafloor at the sampling station. Then, we start taking water samples water at the desired target depths.

Once the CTD rosette is pulled up to the surface, it will be transported to the hangar where we can start taking water samples. Once all of the samples are collected, the remaining water is dumped and then, we can cock the CTD rosette for the next cast.