Spotlight on Jessica McLaughlin

Jessica McLaughlin is an R&D Engineer II specializing in Salinity Analysis & Rosette Support.

My degree is in Ocean Engineering, more focused on underwater vehicles and robotics, but now I get to work in a walk-in fridge on a boat in the middle of the Southern Ocean!

My job varies a lot between what I do on shore versus at sea! On shore, I work in the Calibration Lab at Scripps Institution of Oceanography in San Diego, CA where I calibrate the CTD sensors (conductivity, temperature, pressure, etc.) and the meteorological sensors (air temperature, relative humidity, precipitation, etc.) for our ships. At sea, I work on both salinity analysis and routine CTD rosette maintenance (both bottles & sensors).

Studying salinity is crucial for both chemical and physical oceanography, marine biology, underwater acoustics, and many other oceanographic studies. When we collect salinity samples, we get bottles of saltwater from every depth during that CTD cast. Our CTD on this trip has 36 Niskin bottles, so we can collect up to 36 samples per station.

Jess takes a small water sample from each of the Niskin bottles on the rosette.

Each of the glass bottles is rinsed 3 times and then filled with seawater from the Niskin.

We process samples from two stations at a time, which means we run close to 72 samples every time we’re in the salts fridge—dubbed “salts jail” because one station takes about 1.5 hours, so with two stations you will be in the fridge closer to 3 hours! The best part about hanging out in a walk-in fridge by yourself is that you can sing along to your music at full volume and no one can hear you!

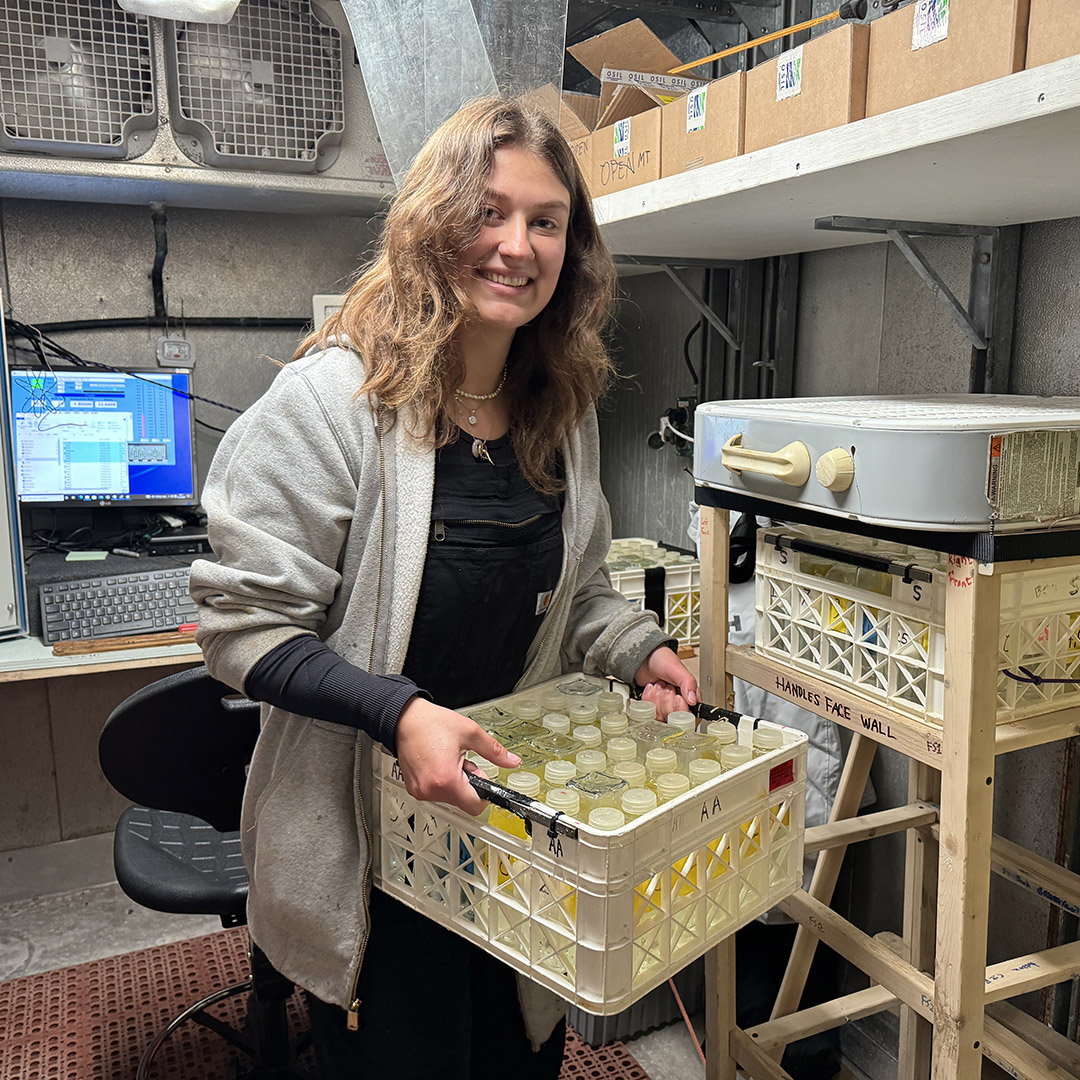

Jess rinses the crate of bottles after sampling.

Jess places a crate of samples from one station into the rack, where it is brought to room temperature by a fan.

The reason we work in a fridge is that we need a temperature-controlled environment for our analysis. Before we can even start our process, the samples must sit for at least 8 hours in the fridge to guarantee they are a uniform temperature that matches the AutoSal*—the salinometer we use. We always have two AutoSals up and running, one as our primary (which we hope to use for the duration of any cruise), and the other as a spare that is at temperature and ready to go. The process of both sampling and running salts are similar; we rinse the bottles or the conductivity cells in the AutoSal three separate times to ensure any previous samples won’t mess with our data. For analysis, after the rinses, we then take a minimum of two conductivity ratio readings from the AutoSal (it’s at least 2 because if the ranges are not with .0005 of each other we must rinse and read again). Bad readings can sometimes happen if there happen to be any salt crystals that formed in the bottle or around the bottleneck and have accidentally gotten into the sample.

*“The instrument is semi-portable, semi-automatic, and is used in the land-based or seaborne laboratory to determine salinity levels in saline samples by measuring the equivalent conductivity ratio to a standard seawater sample.” Guildline Instruments. Technical Manual for Model 8400B.

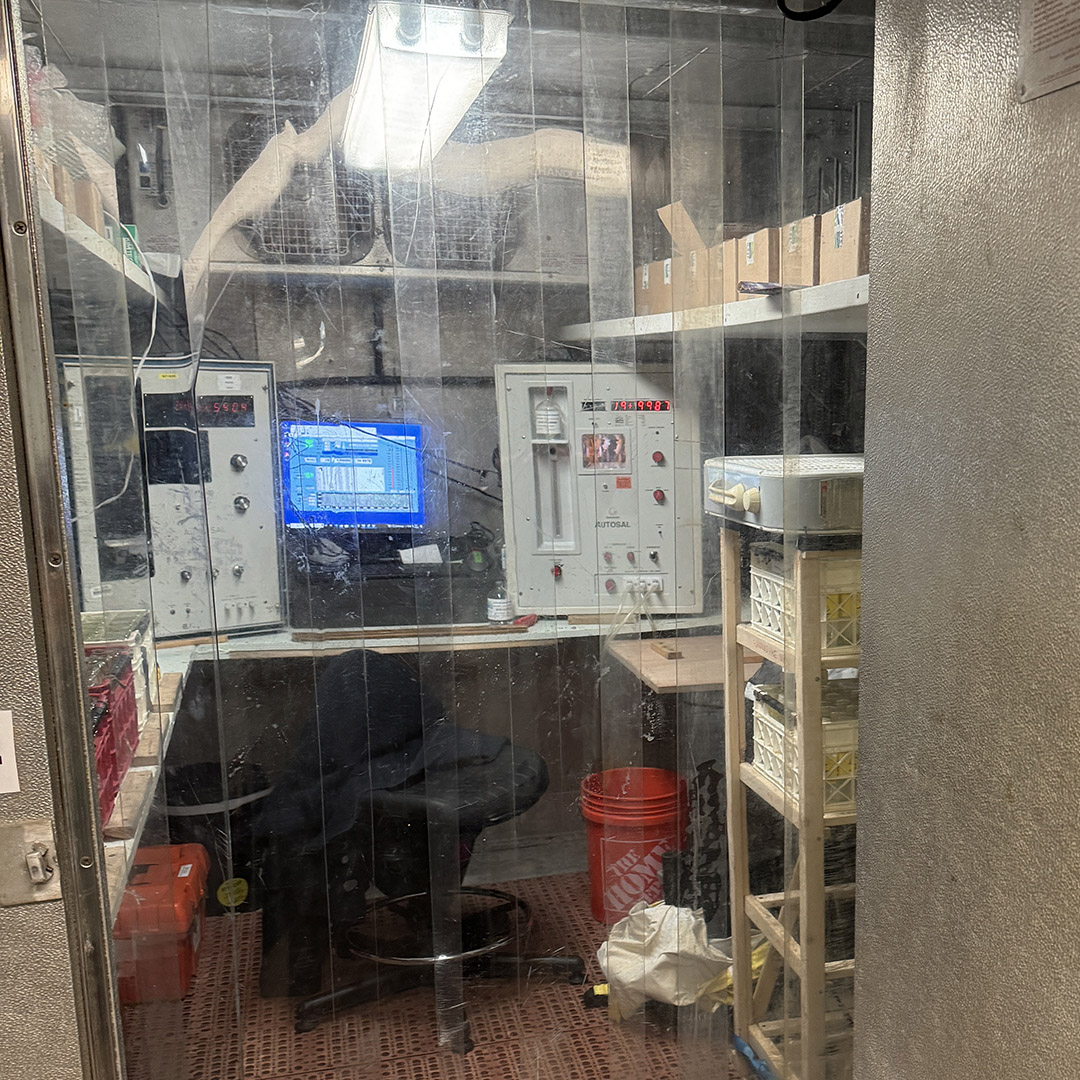

The salt lab fridge provides a temperature-controlled environment for processing the samples.

The primary salinometer (right) and back-up (left) are both kept up and running to ensure samples can be processed.

The other aspect of my job includes taking care of Rosie, the CTD rosette. With so many casts and stations, it’s easy to let little things get overlooked, but that’s why I’m there! I help fix any bottles, O-rings, vents/spigots, lanyards, sensors, and cabling as any issues arise. Or during the event that a Niskin bottle implodes while I am in salts jail, I (with the help of our marine tech, Emmett) swap bottles out at speeds that should qualify us for some sort of Oceanographic Olympics (I definitely wouldn’t win gold but once you’re in the Olympics you’ve basically made it).

Jess works with Marine Technician Emmett Dixon to replace a bottle that went missing on a cast.

Jess works on maintaining Rosie the rosette to make sure that everything is in working order.

When not in salts jail or dealing with the CTD, I’ve passed the time reading, coloring, puzzling, giving presentations about my dog Flick, or watching the icebergs as we pass them by.

Jess with one of the many ’bergs we saw in the Southern Ocean. Selfie by Jessica McLaughlin.

Jess misses her dog, Flick, who is following along from shore. Photo by Jessica McLaughlin.

All images are by Jennifer Magnusson unless otherwise noted.